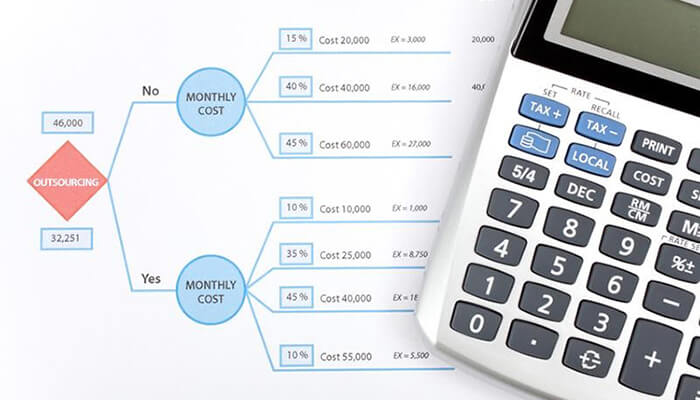

Properly managing a business includes predicting and cutting possible losses along the way. When it comes to outsourcing, many overlook the actual costs and careful planning it takes to start gaining profit.

Outsourcing is an investment, and like most investments, it is risky, which means you must possess some knowledge or you could find yourself in more debts than expected. A good strategy demands preparation for every possible income level, and there are many unique benefits to a good outsourcing strategy, so here are a few essential factors of outsourcing that contain hidden costs.

There are always differences between projected and actual costs. Hidden costs of outsourcing add up to 16% of the purchase price and up to 80% of costs are in the supply chain. Anticipating costs depend on the characteristics of the market, contractors, sales, and distribution.

- Market – The market changes constantly, and keeping up with its shifts can help you avoid a lot of unnecessary spending. Even though China is number one in manufacturing, this may not be the best option for your business. Products damaged by poor handling, limited design flexibility, management costs, are the reasons why you should consider moving the business closer to home. The best way to determine the best course of action is presented in market analysis and data research.

- Contractors – Contractors and management can cost you a lot of money if not given clear directions. Bad collaboration can cause missed market opportunities, loss in sales, and customer returns of the product. In the case of these problems, follow data, monitor the process, and find the source of the problem.

- Sale – Sales equal to inventory and demand. Risks of manufacturing a large scope of the business are extensibility of design and ability to follow changes on schedule. Mismanaged products with no demand could stock up the inventory, damage the company’s reputation, and add expenses. To prevent this from happening, recognize the specific requirements of demands, and outline them.

- Distribution – Distribution and delivery issues occur with a bad choice of supplier and/or poor communication. A contractor’s capacity must match the demands of the company; otherwise, costs of the unneeded inventory arise. If there are too many people involved, their roles must be clearly defined.

Also See: How to Maximize Efficiency For Your eCommerce Merchandise

Time can work for you with a well-selected supplier. There are no advantages to hiring an inexperienced contractor for a lower price. It could only lead to additional expenses if there are problems with the quality of the product and you’ll still need to search for a new supplier with a higher price once too many problems start occurring.

Taking the time to select the right person for the job, someone reliable and flexible, who meets all your expectations, is crucial. But it is only the beginning, after which you have to pay attention to the following details:

- Deadline – Set a realistic deadline based on when the finalization is needed. Work with your team to form a general idea of when it could be finished. Keep open communication lines with the contractor to find a mutually agreeable deadline. Create a plan with mutual responsibility and possible further collaboration.

- Communication – Technology can work for you. Scheduled updates and immediate access to project data help prevent mistakes and save time. It allows employees, as well as the supplier, to work better and faster as a team.

- Motivation – As mentioned before, defined roles are necessary for progressive business. Monitoring the project and giving clear instructions enables better performance, but it is a good idea to let your employees know they are doing a good job. Furthermore, the quality can drop if they are overwhelmed. Make sure they have a day or two to relax and recharge.

Inadequate quality can cause a loss in revenue of up to 12%. Reworking and repairs only build up the price of the product, not to mention the legal costs it includes, and free of charge product repair with warranty and customer returns.

Before production, ask for a sample or define precise instructions in the contract. Being proactive and detecting a problem ahead, prevents additional costs of changing the design. Make improvements in direct support to meet the criteria of customer demands.

Don’t be blinded by the money saving potential of cheap, low quality outsourcing. This process requires devoted planning and you need to develop the best strategy for the type of business you own. In order for it to work, you must look at every angle, calculate losses and benefits and secure a strong business structure.