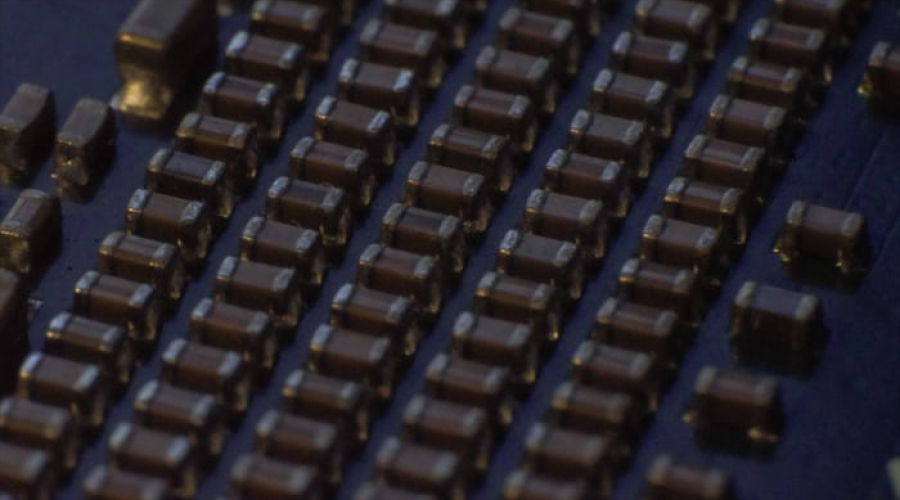

Capacitors—fundamental components in electronic circuits—store and release electrical energy, playing a crucial role; two conductive plates, separated by a dielectric material at their core, enable them to hold an electric charge. This capacity for temporary energy storage renders capacitors indispensable across various applications: they stabilize voltage in power supplies and filter noise in audio systems. Their versatility and simplicity render them a cornerstone of modern electronics: enabling the efficient operation of countless devices.

Capacitors play an essential part in electronic circuits: they manage power delivery by providing steady and reliable voltage to sensitive components; separate AC from DC signals in signal processing; and separate audio, video and communication equipment from audiovisual applications.

Capacitors also play an indispensable part in timing circuits: working alongside resistors they help regulate current flow during specific periods; without them many electronic systems would suffer inefficiency or unreliability, making their contribution essential to technological advances.

Common Issues with Capacitor

The insulating material—referred to as the dielectric—undergoes deterioration or failure, resulting in capacitor leakage: current flows through the capacitor despite being designated not to. Often this problem stems from extended exposure to elevated temperatures; such conditions hasten the dielectric’s breakdown.

Additionally, overvoltage situations subject capacitors to electrical stress exceeding their rated capacities and can precipitate leakage. Poor-quality manufacturing or material defects often cause premature failure; notably, electrolytic capacitors—vulnerable due to their liquid electrolyte—are prone to leakage when they dry out or chemically degrade.

These are only a handful of reasons why capacitors for sale should be procured only from reputable vendors that thoroughly test their products.

1. Symptoms and Detection Methods

Inspectors must actively engage in both visual and technical examinations to detect capacitor leakage: a process marked by performance degradation within the electronic circuit—manifested through erratic power delivery or signal distortion—and visually evidenced by residue or discoloration around the capacitor’s base, signaling seepage of internal electrolyte.

Technicians, employing a multimeter, measure leakage current: an unusually high reading signifies the problem; for heightened precision in detection—an LCR meter evaluates the capacitor’s insulation resistance and unequivocally reveals any existing leakage.

2. Dielectric Breakdown

Dielectric breakdown in capacitors results from the insulating material’s inability to withstand applied voltage; this typically happens because of excessive spikes or surges beyond the device’s rated capacity—or, alternatively, due to internal contamination by dust or moisture that undermines dielectric integrity.

High operating temperatures over time can weaken the dielectric through thermal stress, making it more susceptible to breakdown; poor design or manufacturing defects may intensify these problems—particularly in capacitors functioning in demanding environments.

3. Consequences in Electronic Systems

When a dielectric breakdown occurs, the capacitor essentially loses its charge-storing capacity—resulting in either a short or an open circuit within the electronic system; this can lead to catastrophic failures: power supply disruptions, signal loss or damage to other components.

Occasionally, such breakdowns may overheat capacitors to the point of explosion and present significant safety risks. Prompt diagnosis and resolution of this issue is crucial for ensuring the reliability and safety of electronic devices.

4. ESR (Equivalent Series Resistance) Problems

Equivalent Series Resistance (ESR) quantifies a capacitor’s inherent resistance—this internal friction leads to energy loss during use. Although all capacitors exhibit ESR, an excessive amount may signal trouble; contributing factors: are aging—an inevitable decline in material integrity—and the utilization of inferior components ill-suited for high-frequency endeavors. High ESR severely hampers circuits that demand efficient energy transfer—for example, power supplies and audio amplifiers.

How High ESR Affects Performance?

High ESR severely impacts electronic circuit performance: it induces increased energy dissipation as heat – thus reducing a capacitor’s efficiency and lifespan – and, in power supply circuits, provokes voltage instability that can lead to the irregular operation or failure of connected components.

Capacitors failing to effectively filter signals can cause distortion or reduced sound quality in audio systems; hence, identifying and replacing those with elevated ESR is crucial for optimal circuit performance.

5. Bulging, Swelling or Ruptures

Visible physical damage—such as bulging or swelling from internal pressure increases due to overheating or chemical reactions within the capacitor—is a clear failure indicator; more severe ruptures, which involve splitting or bursting casings, can release hazardous electrolyte fluid into the environment. Prolonged exposure to high temperatures, overvoltage conditions or manufacturing defects typically cause these issues.

Also Read: How To Fix Computer Problems

External Influence on Capacitor Longevity

Native domestic US speakers might express it this way: “The lifespan of capacitors significantly declines with certain external factors; for instance, running them in humid environments or amidst corrosives frequently results in physical degradation—likewise, vibrations and impacts may threaten their structural soundness.” To mitigate these risks, one must use capacitors specifically designed for the environmental and operational conditions they will encounter.

Natural Degradation Over Time

Capacitors naturally degrade with age—even under ideal conditions—primarily owing to the dielectric material’s gradual deterioration and changes in the electrolyte, such as evaporation or chemical transformations (in electrolytic capacitors); consequently, capacitance diminishes while ESR increases, leading to compromised performance. Capacitor longevity varies; it hinges on type, quality and operating conditions—some last for decades; others falter in mere years.

Environmental Factors Affecting Lifespan

Environmental factors significantly influence capacitors’ aging: high temperatures expedite internal chemical reactions—speeding deterioration; likewise, voltage spikes or surges inflict cumulative damage over time.

Humidity, dust and corrosive gases in outdoor or industrial settings can significantly diminish a capacitor’s lifespan; to enhance durability, selecting capacitors rated for anticipated environmental conditions—and employing protective strategies such as meticulous circuit design and consistent maintenance—is imperative.

Also Read: Keyboard Keys Not Working

Diagnosing Capacitor Issues

Maintaining electronic circuits’ health and functionality necessitates accurate diagnosis of capacitor issues: Technicians pinpoint problems early—through a blend of visual inspection and testing tools—to thwart expensive system failures; this section delves into the prime techniques for effective capacitor issue diagnosis.

Visual Inspection Techniques

Visual inspection is one of the easiest and most efficient ways to assess capacitor problems: visible physical damage–such as bulging, swelling or ruptures in its casing–is usually indicative of internal pressure buildup caused by overheating, overvoltage or aging. Technicians can quickly pinpoint components needing replacement by carefully inspecting its exterior; damaged capacitors often display burn marks or discolorations which indicate thermal stress or electrical arcing and thus need replacement quickly.

Visual inspections not only detect physical damage but can also reveal leakage signs: capacitor leakage occurs when electrolyte seeps out from its pores and leaves behind crusty deposits or sticky substances on the circuit board or around its base, potentially destabilizing and potentially harming adjacent components; early identification enables prompt cleaning or replacement; this ultimately saves circuit integrity by limiting further damages.

Using a Multimeter to Test

Visual inspections might reveal clear defects; however, a multimeter proves critical when assessing a capacitor’s electrical properties: one essential function involves using the device to measure capacitance—a test that verifies if the capacitor retains its rated electrical charge.

Technicians can evaluate the need for a replacement by comparing a capacitor’s measured capacitance with its rated value; significantly reduced capacitance undermines effective functioning, resulting in circuit performance issues.

An essential examination consists of assessing for resistance or short circuits: the multimeter measures resistance; a performance capacitor briefly displays low resistance—indicating charge accumulation—before incrementally transitioning to an open circuit, signaling infinite resistance.

When the multimeter displays a consistently low resistance or signals a short circuit, it suggests that the capacitor has likely sustained damage—necessitating its replacement; this method proves highly effective in detecting internal defects which may elude external visual inspection.

Also Read: Green Technology Examples

Wrap up

Preserve capacitors’ health—and thus the integrity of electronic circuits—demands a blend of knowledge, diligence and preventative care. Understanding the root causes of capacitor failure; and employing best practices in circuit design and maintenance; each step fortifies electronic systems’ longevity and reliability.

Capacitors may be small but assume a monumental role in device functionality—their upkeep is imperative. Engineers and technicians, by adopting preventative measures and being proactive in troubleshooting, can guarantee their circuits’ robustness and efficiency for the long term: a dedicated investment in capacitor care now will yield dividends—fewer disruptions, enhanced performance and increased peace of mind—in the future.